Solving the

big picture

Solving the

big picture

Sustainability is woven into our very DNA at SAAM Textiles. It’s part of everything we are, everything we do, and everything we strive to be.

Check Out Our 2023

Sustainability Report

SUSTAINABLE ACHIEVEMENT

ARAMS Textiles( SAAM TEXTILES 100% subsidiary) stands as a shining example of excellence in the Indian textile industry.

We are deeply committed to environmental stewardship and sustainability across all aspects of our operations. Recognizing the importance of minimizing our ecological footprint, we have implemented a range of initiatives aimed at reducing resource consumption, minimizing waste, and promoting responsible production practices.

Green Manufacturing Processes- Solar system

Zero Fossil Fuel Plant Adoption- Bio Husk

Water Conservation Measures- ETP & MEE

Arams Textile

ARAMS Textile fosters a work culture built on collaboration, innovation, and respect. With a diverse workforce of approximately 500+ employees, we believe in creating an inclusive environment where every individual’s contributions are valued and respected

Arams Textile fosters a work culture built on collaboration, innovation, and respect. With a diverse workforce of approximately 200 employees, we believe in creating an inclusive environment where every individual’s contributions are valued and respected

- Zero Fossil Fuel Plant : Our plant exclusively utilizes mustard crop waste, known as Bio husk, to generate steam in our boiler, making us the world's first fabric finishing plant with this capability.

- ZERO Liquid Discharge & Water Initiatives : Our fabrics are "WATER POSITIVE," with no dyeing process, resulting in a 70% reduction in water usage. We recycle 95% of the minimal water used through our RO (Reverse Osmosis) plants. Rainwater Harvesting is in place, and 100% of plant water undergoes ETP and reverse osmosis, with 93% reused and zero discharge of evaporated water.

- Modern Infrastructure : Our factory is equipped with modern infrastructure and facilities to support efficient production processes. From automated machinery to precision control systems, we leverage technology to optimize productivity and quality.

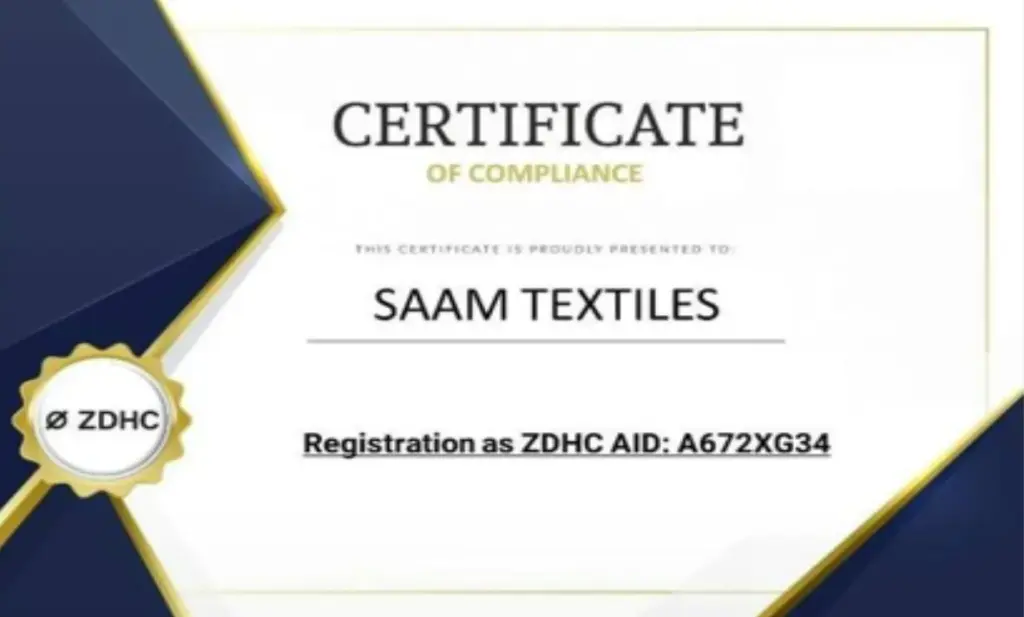

- Certifications and Compliance : ARAMS Textiles is committed to meeting and exceeding international sustainability standards and certifications. We adhere to rigorous environmental regulations and certifications such as ISO 14001, OEKO-TEX, ZDHC and Global Organic Textile Standard (GOTS) demonstrate our commitment to environmental responsibility and transparency.

- Safety First

- Sustainable Practices

- Modern Infrastructure : Our factory is equipped with modern infrastructure and facilities to support efficient production processes. From automated machinery to precision control systems, we leverage technology to optimize productivity and quality.

- Compliance and Quality Assurance : Our factory adheres to strict quality control measures and regulatory standards to ensure the integrity and safety of our products.

- Certifications and Compliance : Arams Textile is committed to meeting and exceeding international sustainability standards and certifications. We adhere to rigorous environmental regulations and certifications such as ISO 14001, OEKO-TEX, and Global Organic Textile Standard (GOTS), demonstrating our commitment to environmental responsibility and transparency.

ISO 14001:2015

Environment Management System

OEKO-TEX Standard 100

World's Best-Known Label for Textile Safety

ZDHC MRSL

Zero Discharge of Hazardous Chemical Manufacturing Restricted Substances List

Global Organic Textile Standard

Voluntary product standard for tracking and verifying the content of recycled materials in a final product

Better Cotton Initiative

Non-profit, multistakeholder governance group that promotes better standards in cotton farming and practices across 21 countries

Wind & Solar Power

As a Comprehensive source for all our energy supply to our factories.

Water Positive Fabric

This differentiates us from other suppliers

Training to Employees

100% Training to Employees on business ethics & human rights.

Beyond Borders: Solar Solutions

for cleaner future-

More than 50% of plant rea is covered with Green spaces.

- SAAM's solar power plant is located at both facilities to strengthen our commitment towards sustainability.

- These plants are proudly generating constant renewable energy to our manufacturing set ups.

- TOTAL SOLAR UNIT CAPACITY- 1690.14KW

Waste and Hazardous Material Management

We follow the ‘Reduce, Reuse and Recycle’ principle for waste management across businesses to manage our waste generation and disposal.

We are ISO 14001:2015 Environment Management System Certified company for the sites. We are committed to prevent the pollution, minimize waste and conserve natural resources.

Recycled Fabric Initiative at Saam

Liva Reviva- Alternative to Regular Viscose Fibres.

Birla Cellulose's Liva Reviva follows the principles of circular textiles and is made using pre-consumer textile - waste. Liva Reviva viscose holds the distinction of RCS (Recycled Claim Standard).

Source Verification and Supply Chain Transparency

Unique molecular tracer inside the fiber for source verification at all stages and supply chain traceability through Blockchain.

Sustainable Forestry

Liva Reviva is produced from Low Water Consumption with and Less GHG Emissions

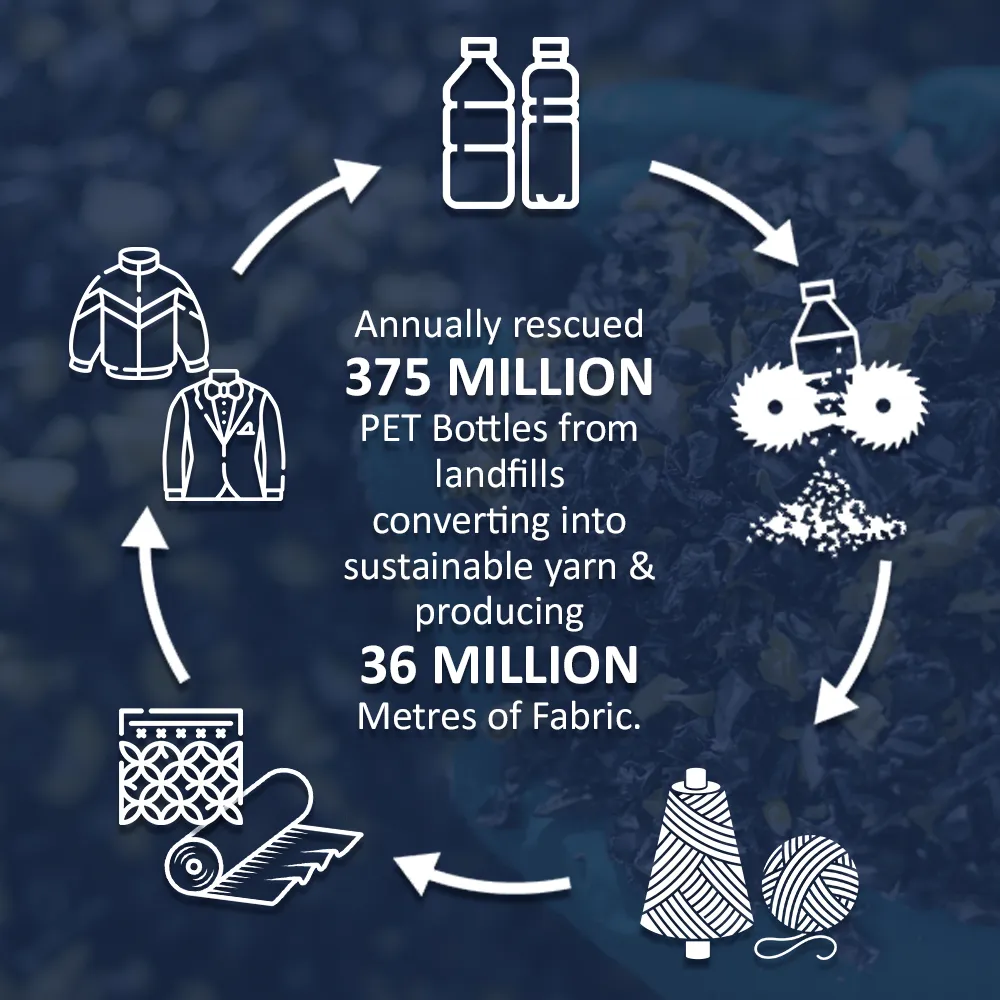

Recycled Polyester Initiative at Saam

Recycled Polyester Initiative at SAAM Textiles

- Unlike virgin polyester, recycled polyester uses PET as the raw material. This is the same material that is used in clear plastic water bottles. Recycling these bottles to create fabric prevents them from going into landfills.

- The process of converting PET into recycled polyester consumes 33-35% less energy than in the case of virgin polyester.

- Using recycled polyester reduces our dependence on natural resources(crude) as the primary raw material for our manufacturing.

Material Efficiency

Better Cotton Initiative (BCI)

We follow the BCI standard system for Better Cotton Principles and Criteria, which promotes the production of better cotton through various guidelines.

Global Organic Textile Standard (GOTS)

We are certified with GOTS, worldwide leading textile processing standard for organic fibers, including ecological and social criteria.

This certification means we can export our products in all the major markets.

Global Recycled Standard (GRS 4.0)

ZDHC-WATER WASTE

We are also certified with Zero Discharge Of Hazardous Chemical Manufacturing Restricted Substances List (ZDHC) and OEKO-Tex 100 Standard.

Using chemical formulations that conform to the ZDHC MRSL allows suppliers to assure themselves, and their customers, that banned chemical substances are not used during production and manufacturing processes.

Water Management Initiatives

Our Strategies

- We are operating towards our LEED-certified finishing unit in Bhilwara and an IGBC-certified weaving unit in Kisangarh.

- We are part of an ESG-focused association and actively engage in ongoing practices related to Higg and GHG emissions reduction.

- We are pioneering the complete elimination of fossil fuels, specifically coal, by utilizing Bio Husk, a first-of-its-kind initiative in India.